Gas Seal Black is a four-layer, low density polyethylene membrane reinforcing grid with an integral aluminium foil.

BENEFITS

- Manufactured from virgin material, not recycled waste

- Separate damp proof membrane not required

- Robust jointing and sealing system

- Welded joints possible

- Single wound membrane with zero creases

- Two colour membrane for on-site quality control

- Suitable for use where radon, carbon dioxide, methane and hydrocarbon vapours are present

- Complies with latest codes of practice as published by CIRIA and BRE

APPLICATIONS

- Combined ground floor damp proof membrane and gas barrier

APPLIED TO

- Sand blinding

- Suspended floors

- Ground bearing slabs

TYPICAL USES

Gas Seal Black is typically used as a low density, polyethylene gas barrier and damp proof membrane in concrete floors above and below the slab. The installed product protects the structure against moisture, radon, methane, carbon dioxide and hydrocarbon vapours from the ground. The product is suitable for use on ground bearing reinforced concrete slabs, suspended beam and block floors or precast concrete slabs. When used for hydrocarbons, the product must be applied on top of the slab, with the ground below vented.

DURABILITY

Subject to normal conditions of use Gas Seal Black will remain effective against the ingress of water and water vapour, and will restrict the ingress of radon, methane, carbon dioxide and hydrocarbon vapours during the lifetime of the building.

SPECIFICATION

J40 Flexible sheet waterproofing / damp proofing Clause 140 Loose laid polyethylene gas retardant damp proofing. Please consult RIW for further information.

INDEPENDENT AUTHORITY

Gas Seal Black has been awarded a BBA Certificate No. 14/5156 covering its use as a low density, polyethylene gas barrier and damp proof membrane in concrete ground floors, above and below the slab not subject to hydrostatic pressure, to protect the building against moisture, radon, methane and carbon dioxide from the ground.

PERFORMANCE & COMPOSITION

| Form | loose laid composite sheet |

| Colour | black/white |

| Overall thickness | 0.6mm |

| Roll size | 2m wide x 50m long* |

| Weight | 350g/m2 = 35kg/roll |

| Laps | 150mm |

Tensile strength MD EN 12311-1 CD | 600N/50mm 480N/50mm |

| Elongation EN12311-1 | 20% |

Nail tear resistance MD EN 12311 -1 CD | 330N 400N |

Radon permeability (m2 s-1 Pa-1) Methane gas permeability (m2 s-1Pa-1) Carbon dioxide permeability (m2 s-1Pa-1) | 8.00 x 10-15 1.56 x 10-19 2.58 x 10-19 |

The above performance figures are typical values and should not be considered a product specification. *Other roll sizes available.

ANCILLARY PRODUCTS

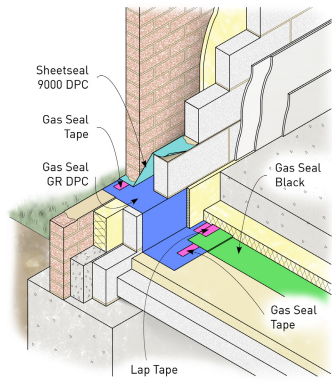

RIW produce a range of ancillary products for use with Gas Seal Black which include:

Gas Seal Tape - double-sided self-adhesive butyl tape for sealing between overlaps in the membrane.

Lap Tape - single-sided self-adhesive PVC tape for sealing edges of lapped product.

Lap Tape RB - reinforced single-sided self-adhesive bitumen tape for sealing edges of lapped product and repairs to membrane.

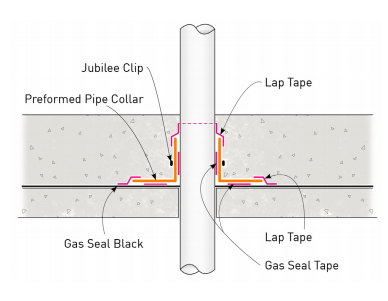

Preformed pipe collars - flexible collar for sealing around pipe penetrations.

Sheetseal GR - self-adhesive sheet membrane for gas resistant waterproofing applications.

Gas Seal GR DPC - gas resistant damp proof course/ cavity tray for building into masonry.

Geo-vent - cuspated HDPE venting geo-composite incorporating geotextile to one side.

T connectors - geo-vent end connector incorporating 25mm slot for geo-vent.

Peri-vent sets - periscopic vent complete with airbrick and geo-vent adaptor.

Pro-fleece - textile fleece for protection of applied gas membranes.

Gas cloaks - standard or bespoke cloak units to facilitate membrane application.

CONSTRUCTION

GENERAL

All construction should conform with the Building Regulations, Codes of Practice and British Standards in current use at the time the building is being constructed.

PREPARATION

The membrane should be laid on a smooth surface, free from voids, hollows and objects which may damage the membrane. If used below a ground bearing slab, the product may be laid on a sand blinding.

APPLICATION

The completed gas proofing system must cover the entire footprint of the building. Gas Seal Black should be unrolled onto the prepared surface, and be smoothed out as necessary. The product must be installed with the black side uppermost. Subsequent rolls should then be lapped onto the previous roll by 150mm, and be sealed using Gas Seal Tape placed centrally in the lap. Lap Tape should then be laid over the edge of the upper sheet, by 50mm, and be adhered down onto the lower sheet. Pipe penetrations should be sealed using Preformed Pipe Collars; sealed to the membrane, and pipe using Gas Seal Tape and Lap Tape; see Pipe Penetration Detail. Gas Seal GR DPC should be used to provide continuity through the walls, with Gas Seal Black lapped and sealed onto it using Gas Seal Tape and Lap Tape as before. Damaged areas should be patch repaired as necessary, using similar lapping/sealing details. Gas Seal Black will achieve 2 Points in accordance with BS8485 when installed by qualified specialists and independently validated. Where additional points are required, our Passive Venting System may need to be incorporated.

SPECIFIC USES

Gas Seal Black should be installed with the ancillary products required, in accordance with current guidance for gas protection systems; including BRE211 / 414, CIRIA C665 & BS 8485.

SAFETY

Full health and safety instructions are contained on the product material safety data sheets, and these must be referred to before use.

SUPPLY

AVAILABILITY

All products can be obtained through Builders Merchants or approved stockists. A list of approved stockists is available from RIW’s offices.

PACKAGING

Gas Seal Black 2m wide x 50m long rolls

STORAGE

The rolls must be stacked on a flat surface, kept under cover and protected from sunlight and mechanical damage.

TECHNICAL SERVICES

The Technical Department is available to advise on individual projects and to prepare or assist in the preparation of specifications and drawings. We can also offer design guidance to satisfy the requirements of BS8485 and CIRIA C735. A list of experienced applicators of our materials is available from RIW’s offices, along with a list of independent consultants providing validation and integrity testing services.

Download

Click here to download this information in PDF format.