Flexiseal Pro is a two-pack solvent free polymer modified epoxide coating which cures to give a continuous tough but flexible waterproof coating.

Flexiseal Pro Primer is a two-pack solvent free black liquid modified epoxide surface conditioner that can be applied to damp surfaces.

BENEFITS

- Water and water vapour barrier

- Colour coded for quality control

- Seamless & fully bonded coating

- Can be applied in one coat to horizontal areas

- Tough & flexible, able to accommodate differential movement

- Cold applied by hand or spray

- Simplifies application to irregular profiles & complex details

- Can be applied to damp surfaces

- High substrate adhesion

- Good chemical & UV resistance

- Effective barrier to carbon dioxide & methane

APPLICATIONS

- Basement and sub-structures

- Podium decks

- Elevated decks (terraces & balconies)

- Ground floor DPM

- Plant rooms & containment bunds

- Superstructures

- Gas proofing

APPLIED TO

- Concrete

- Masonry

- Steel

TYPICAL USES

Flexiseal Pro is used where a high performance tanking, damp proof membrane or containment system is required. The product prevents water ingress to basements, or other below ground structures as well as through buried roofs and elevated deck areas such as terraces and balconies. Flexiseal Pro can also be used as a containment system in plant rooms & other bunded areas, and will bridge static & dynamic cracks where further movement is expected. Flexiseal Pro can be applied in one single coat to horizontal areas and two coats to vertical areas. All surfaces should be sealed with one single coat of Flexiseal Pro Primer, to condition the substrate and aid adhesion of the coating. When designing Type A structures (as classified in BS 8102: 2009), the product applied correctly is capable of providing the levels of protection required for Grades 1, 2 & 3 basements. Flexiseal Pro is not to be used in contact with potable water systems.

DURABILITY

Subject to normal conditions of use Flexiseal Pro will provide an effective barrier to the transmission of liquid water and water vapour for the life of the structure

SPECIFICATION

J 30 – Liquid Applied Tanking/Damp Proofing in accordance with NBS Clauses.

J 31 - Liquid applied waterproof roof coatings in accordance with NBS Clauses.

Please consult RIW for further information.

INDEPENDENT AUTHORITY

Tests carried out by VINCI Technology Centre show that Flexiseal Pro has excellent crack bridging capability, adhesion and resistance to negative water pressure.

ANCILLARY PRODUCTS

RIW produce a range of ancillary products for use with Flexiseal Pro which include:

Cementfill FC - Cement based waterproof fairing coat and repair mortar for filling minor holes, voids and defects.

Cementfill HB - Cement based waterproof high build repair mortar for profiling and providing fillets.

Cleaning Solvent - a liquid for cleaning tools, equipment, etc. (must not be used as thinners).

Double Drain - a drainage board which protects the membrane during backfilling operations and also promotes drainage of water away from the structure.

Protection Board - a 3mm rot proof bitumen board to prevent damage to the waterproof membrane during backfilling operations.

Adhesive Tape - a 150mm wide double sided tape for temporarily adhering Protection Board or Double Drain to the membrane.

Sheetseal 9000 DPC - a range of high performance polymeric dpc's, and pre-formed cavity trays, compatible for use with all RIW membranes.

CONSTRUCTION

All construction should conform with The Building Regulations, Codes of Practice, and British Standards in current use at the time the building is being constructed. In particular, it is recommended that reference is made to BS 8102: 2009.

PREPARATION

All Surfaces: Should be smooth, clean, sound and free from frost, oil, grease, condensation and other contamination. Any voids or hollows must be made good to a flush finish, with a suitable filler. Any sharp edges or high points should be eliminated. Powdery or flaking surfaces should be removed by suitable means. All standing water should be removed. External corners should be chamfered or rounded where required, to assist application.

Concrete Surfaces: Horizontal surfaces should preferably be smooth, however lightly tamped (2-3mm peak to trough profile maximum), brushed or floated surfaces are preferred.

Masonry: Should be sound with joints flush pointed or ‘bagged out’ with Cementfill or similar before the membrane is applied. Open textured surfaces should be sealed with Cementfill FC or a sand/cement slurry to provide a suitable surface. If existing surfaces are very rough, they may require preparing with a Cementfill FC or a sand/cement render coat.

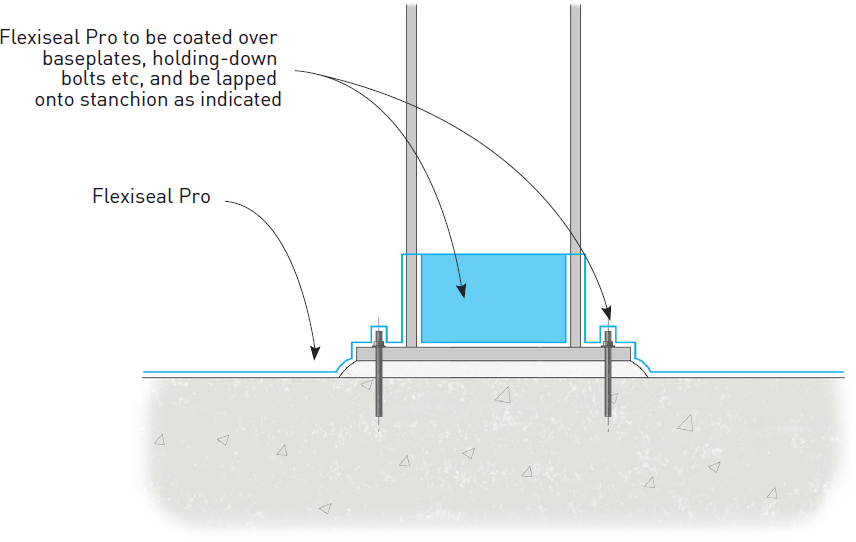

Metal surfaces: Should be wire brushed or sand blasted and pre-treated with a steel primer prior to the application of the Flexiseal Pro Primer and Flexiseal Pro. Corroded metal should also be treated with an anti-corrosive primer. Flexiseal Pro Primer is compatible with most commonly encountered steel primers including alkyd, chlorinated rubber and epoxy based paints. Consult RIW for galvanised steel and/or other treatments.

APPLICATION

General: Application of Flexiseal Pro and Flexiseal Pro Primer should not be attempted in temperatures below 5°C. Apply one coat of Flexiseal Pro Primer by brush, roller or spray to all surfaces. Flexiseal Pro Primer must be allowed to become tacky to the touch or dry before overcoating. Flexiseal Pro and Flexiseal Pro Primer should not be thinned and should be applied as supplied.

Do not apply primer onto existing membrane at overlaps, etc, unless directed otherwise.

Flexiseal Pro Primer and Flexiseal Pro are supplied as two pack systems, with a base component and a hardener.

The base component should be mechanically stirred for 3 minutes, and then the hardener component added and mixed thoroughly until a uniform colour is achieved. Ensure the entire contents of the hardener component are added to the base component before mixing.

Do not split base or hardener components. Flexiseal Pro Primer and Flexiseal Pro should be applied immediately after mixing.

Apply Flexiseal Pro Primer in one coat at a minimum application rate of 4m2/litre.

Apply Flexiseal Pro in one coat to all horizontal areas at a minimum application rate of 1m2/kg, and in two coats to all vertical areas at a minimum application rate of 2m2/kg.

Good ventilation is necessary to obtain a proper cure. At 23°C, Flexiseal Pro Primer will require 4 - 6 hours before overcoating with Flexiseal Pro, which at 23°C will require 6 hours to cure. Curing will stop at temperatures below 5°C. Flexiseal Pro Primer should be overcoated with Flexiseal Pro within seven (7) days of application. Where a second coat of Flexiseal Pro is required, it should applied within 7 days of the first coat. If this is not possible advice should be sought from the RIW Technical Department.

Flexiseal Pro has been independently proven to exhibit good dynamic crack bridging capabilities, however additional reinforcement of the coating may be required at angles, joints, pipes etc, which can be undertaken incorporating Flexiseal Pro Scrim between two coats of Flexiseal Pro. Seek advice from the RIW Technical Department.

Manual: Flexiseal Pro Primer and Flexiseal Pro should be applied using a brush, medium pile roller or spray. For details of specialist waterproofing contractors, please consult the Technical Department.

Do not allow water to enter the product.

PERFORMANCE & COMPOSITION

| FLEXISEAL PRO PRIMER | FLEXISEAL PRO MEMBRANE | |

| Form | liquid | Thixotropic liquid |

| Colour | Black | Red |

| Specific Gravity - Base - Hardener | 1.16 g/ml 1.03 g/ml |

|

| Solids content | 100% (w/w) | 100% (w/w) |

| Flash point - Base - Hardener | 140˚C 90˚C | 150˚C 90˚C |

Coverage* | 4m2/litre 4m2/litre | 1m2/kg/coat 2m2/kg/coat |

Number of coats | 1, minimum | 1 (Horizontal) |

| DFT of coating | 200 microns | 0.9mm min |

| Minimum lap | 100mm | |

| Curing time | 4-6 hours (slightly tacky). | Touch dry: 6 hours min |

| Full chemical cure | 7 days | 7 days |

| Overcoating time | Minimum: 4-6 hrs, when tacky to the touch Maximum: 7 days | Minimum: 6 hrs Maximum: 7 days |

| Elongation | N / A | 97% |

| Tensile strength | N / A | 11.6N/mm² |

| Application temp limits | 5 – 35˚C | 5 – 35˚C |

| Preparation of liquid | Stir well by mechanical means | Stir well by mechanical means |

| Pot life | 20mins @ 23˚C | 20mins @ 23˚C |

| Shelf life: from date of manufacture | 12 months | 12 months |

| PHYSICAL / CHEMICAL RESISTANCE (SPILLAGES) | ||

| Sulphate resistance | N / A | 50,000 ppm |

| U.V. resistance | N / A | Good |

| Brine | N / A | Resistant |

| Dilute mineral acids | N / A | Resistant |

| Dilute alkali solutions | N / A | Resistant |

Diesel/Petrol | N / A | Resistant |

| Anti-freeze | N / A | Resistant |

| Lubricating oil | N / A | Resistant |

| White spirit | N / A | Resistant |

| 50% Caustic Soda | N / A | Resistant |

These performance figures are typical values and should not be considered a product specification.

*Figures quoted are theoretical coverage rates. Actual coverage may vary depending on nature of substrate.

QUALITY CONTROL

Flexiseal Pro is a red coating; when applied to the black Flexiseal Pro Primer it becomes a two colour system which allows for easy identification of any areas that do not have the appropriate coverage of Flexiseal Pro.

Flexiseal Pro wet film thickness can also be measured during installation with formal wet film thickness assessments using a ‘Wet Film Comb’ whilst the coating remains wet during its application; this allows minimum wet film thicknesses to be achieved throughout. Consult RIW Technical Department for further advice.

SPECIFIC USES

Tanking: In general, Flexiseal Pro should be fully supported, to resist hydrostatic pressure, when used for tanking. Independent tests show Flexiseal Pro has good resistance to negative water pressure, so in some low risk tanking situations, subject to negative water pressure, Flexiseal Pro can be used without being fully supported. However, the RIW Technical Department should always be consulted to undertake a full assessment of these situations, and if deemed acceptable RIW will provide the appropriate guidance in writing: without this we cannot accept responsibility.

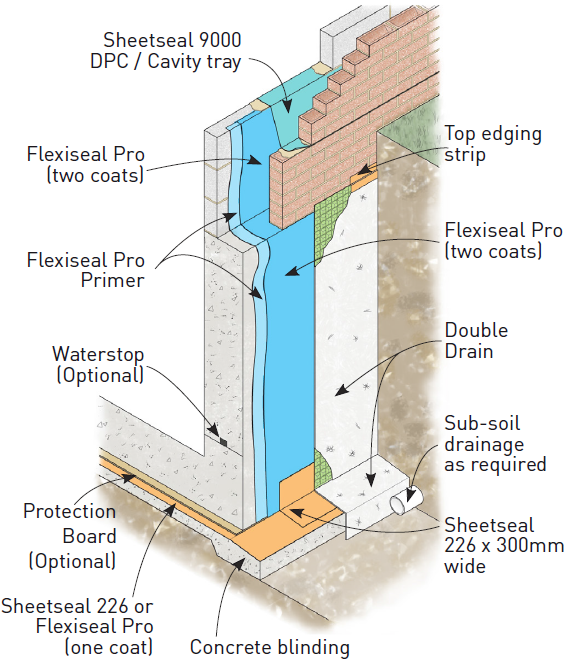

External tanking: Should be carried out as illustrated in Detail 1 of this literature. The horizontal coating or membrane should be laid on a solid concrete blinding to project at least 150mm beyond the outer face of the structure. The base structural slabs and the walls should be formed, and the vertical Flexiseal Pro should then be applied. The membrane should then be protected from backfilling using Double Drain or Protection Board, to suit.

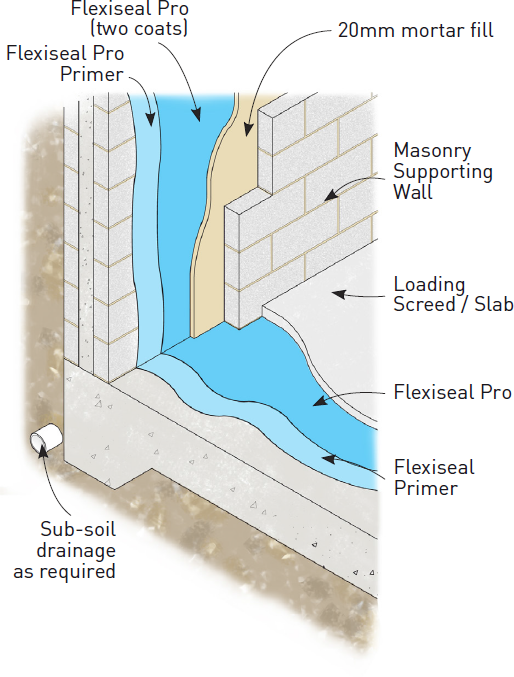

Internal tanking: Should be carried out as illustrated in Detail 2 of this literature. A loading coat of brick, block or concrete should be constructed immediately after the membrane has cured. If brick or block is used, a 20mm minimum cavity should be left between the membrane and the loading skin. This cavity must be filled with sand/cement mortar fill as work proceeds.

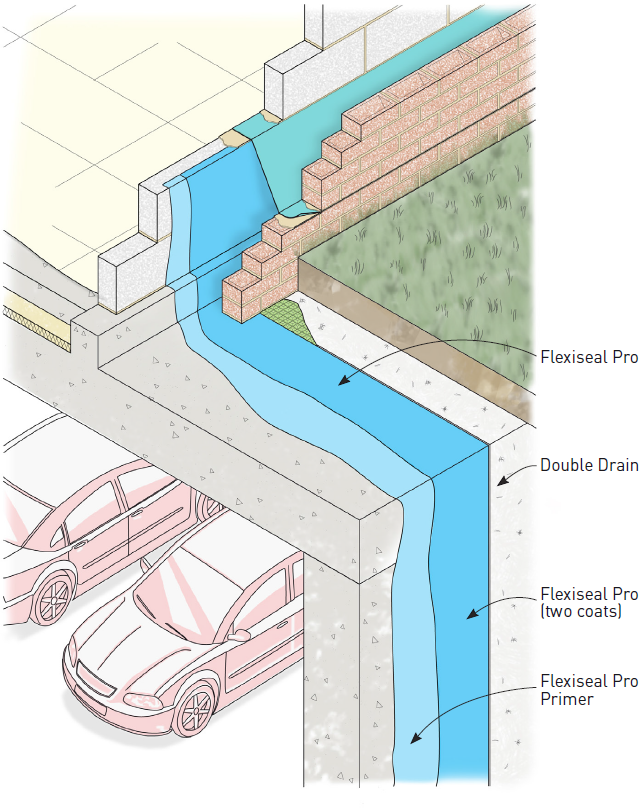

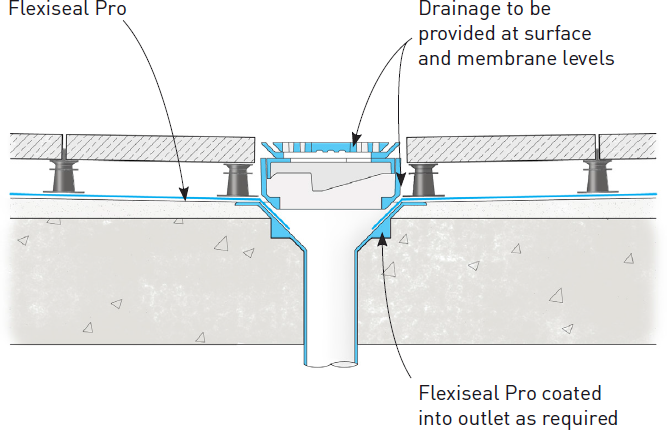

Deck Areas: Should be installed as shown in Detail 3, although it is good practice, where possible, to apply Flexiseal Pro on a substrate laid to falls to outlets as necessary. The membrane should be covered and protected as soon as possible after application

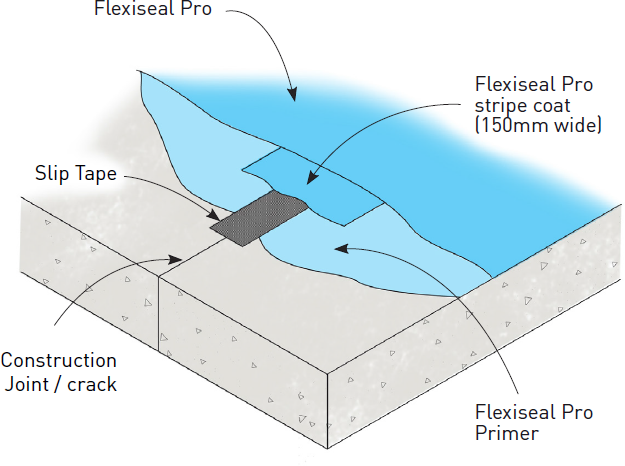

Crack bridging: Flexiseal Pro can be applied over a static / dynamic crack in the substrate as shown in Detail 4. The use of RIW Universal Tape (or other slip tapes) over joints, beneath Flexiseal Pro, debonds the membrane allowing dissipation of stresses over a wider area. A 150mm wide stripe coat of Flexiseal Pro, and/or the introduction of the Flexiseal Pro scrim can be used to increase crack bridging capability and tensile strength of Flexiseal Pro. When dynamic crack bridging is required, the RIW Technical Department should be consulted.

Expansion & movement joints: Generally, Flexiseal Pro is used in conjunction with movement jointing systems, such as Multijoint, where the joints have been designed into the structure to accommodate expansion and movement. In these circumstance, please consult the RIW Technical Department to discuss the most appropriate solution.

SAFETY

Flexiseal Pro products can affect sensitive skins. Gloves or barrier cream should always be used by operatives and hands should be thoroughly washed at the end of each working period. Normal levels of air change are acceptable, however wear a suitable respirator if application is in an enclosed space. Do not allow the product to enter watercourses. Full health and safety instructions are contained on the product safety data sheets (SDS), and these must be referred to before use.

SUPPLY

AVAILABILITY

All RIW products can be obtained through Builders Merchants or approved stockists. A list of approved stockists is available from RIW’s offices or via our website.

PACKAGING

Flexiseal Pro (2) | 5kg and 20kg packs |

| Flexiseal Pro Primer (2) | 5 litre and 15 litre packs |

| Flexiseal Pro Scrim | 100mm x 10m rolls |

STORAGE

The shelf life of unopened containers, stored in dry, warm conditions, is 12 months.

TECHNICAL SERVICES

The RIW Technical Department is available to advise on individual projects and to prepare or assist in the preparation of specifications and drawings. A list of experienced applicators of RIW materials is available from RIW’s offices.

The information in this literature was correct at the time of going to press. However, we are committed to continually improving our products and reserve the right to change product specifications.

For the latest information, please consult RIW. Conditions of use are beyond our control, therefore we cannot warrant the results to be obtained.

For the latest information, please consult RIW. Conditions of use are beyond our control, therefore we cannot warrant the results to be obtained.

DOWNLOAD

Click here to download this information in PDF format.